The hospital’s Central Sterile Supply Department (CSSD) ensures that all medical supplies and equipment are carefully cleaned. This crucial function aids in protecting patients from potentially harmful germs and other diseases. One’s duties as a central sterile technician include constructing surgical instrument trays, cleaning reusable equipment, including endoscopes and dialyzer sets, and preparing surgical instruments.

In the hospital, a sterile processor provides sterilized supplies to all departments, including specialty units and ordinary wards in OPDS. The Central sterile supply department is the hospital’s central nervous system, where the fight against infection is waged.

They also collect and distribute dirty utilities to various hospital departments (TSSU). Medical personnel use it later in the hospital’s operating room and other aseptic operations. For instance, bandaging, stitching, and catheterization in an operating room, maternity ward, or pediatric ward.

The sterile processing technician certification program can assist students in gaining the skills necessary to join the central services team of any hospital. The training aims to provide students with the expertise and abilities needed to launch a successful and in-demand career in healthcare. Certification establishes the credibility and competence of sterilization training by validating competencies.

Usually, after being carefully cleaned, an instrument from the operating room is brought to the decontamination area and placed in a washer/disinfector before being placed in a big ultrasonic bath or ultrasonic humidifier. It would then be moved to a preparation and packing section to prepare the instrument for sterilization.

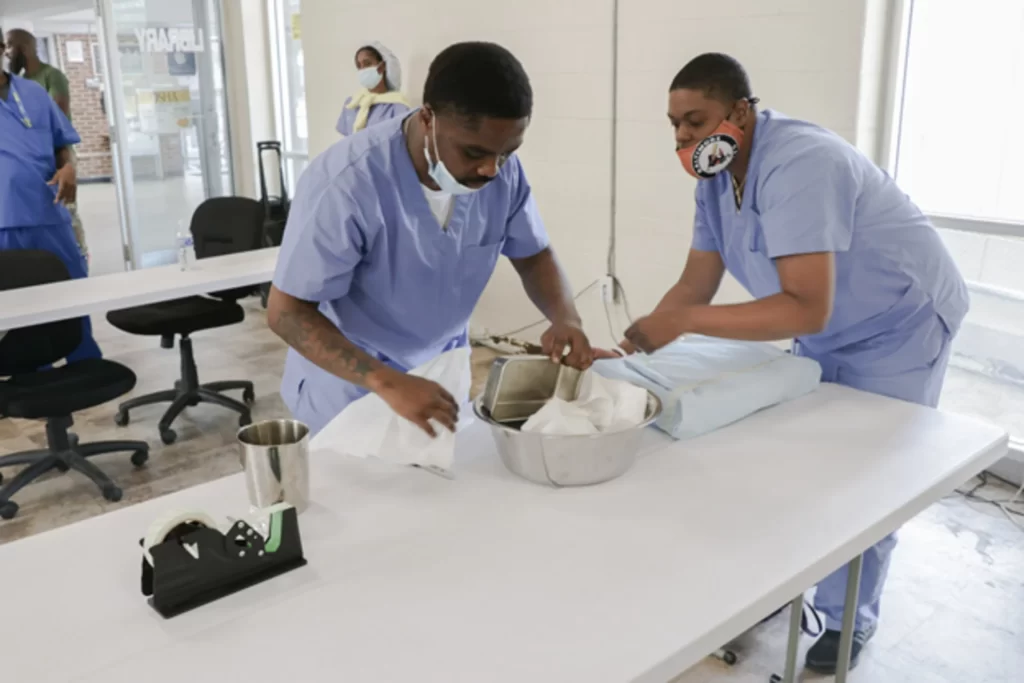

Then, it will be sterilized using one of several different sterilization procedures. Finally, the equipment will be placed into a sterile space to store until it is required again. A central sterile technician must wear personal protective equipment (PPE) as a safety measure to safeguard against exposure to potentially contagious germs.

Cleaning and inspection of equipment are of the highest priority in this area. The physical or chemical procedure known as decontamination makes an object that might be contaminated with hazardous microorganisms suitable for repeated operation. Decontamination is done to prevent central sterile technicians who prepare and package medical devices from getting sick from pathogens on those devices. This is done to avoid the spread of diseases to those sterile technicians.

This area is for drying and packaging purposes. Upon cleaning and inspection, sterile processors put the equipment into sets or platters. They follow preparation instructions that provide step-by-step directions for putting each set or platter together. To maintain their sterility until the point of use, instruments and other things ready for sterilization must be packaged.

The packaging materials and methods must permit the sterilant to come into touch with the device during the sterilization procedure and safeguard the device against contaminants during storage and handling before use. The interval between sterilization and use can be anywhere from a few moments and several weeks or months. The packaging material chosen must also enable aseptic device disposal.

The surgical sterilization tech preparation and packing area will receive the instrument once it has been cleaned manually, mechanically, or both. The instrument packs are prepared for sterilization and are then ready to be sterilized using one of several techniques. The sterilization process is a method to rid something of microbes or other life forms, whether spores or in vegetative condition—eliminating all microorganisms from a surface or substance.

The sterile chamber will store items still being prepared for distribution, protecting them from contamination before usage. A trained sterile processor should also be able to appropriately assemble medical equipment for storage. Surgical sterilization tech assures sterile supplies don’t go out of date, avoids sterility problems associated with events, delivers clean supplies to the appropriate locations, and collects used stores.

In the healthcare industry, central sterile technician supply processing technicians are essential. In addition to assembling, sterilizing, and decontaminating medical equipment, they are also responsible for its storage and distribution. It’s a position that calls for knowledge, precision, and familiarity with medical jargon.

For patients to receive safe and efficient medical care, the work of the Central sterile support department and clean technicians is crucial. To perform their duties effectively, a sterile technician must be familiar with every component of a sterile processor. This entails knowing the proper methods for assembling, sterilizing, stocking, and distributing tools and supplies.

Read More –