When it comes to infection prevention, there’s little room for error and sterilisation failures can quietly undo even your best efforts. If you lead an SPD or handle compliance, it is essential to understand how mistakes occur and how to prevent them.

This article explains the most common reasons for sterilisation to fail, explains their effects, and shares methods to stop them before patients are affected.

After going through the cycle, everything seemed okay, but it didn’t work out, and something happened. What exactly results in a sterilisation failure? Most of the time, it is just a little, easily avoidable error. We’ll look at the most usual issues a bit more closely.

If instruments are packed too tightly, steam won’t be able to reach every item. This is considered one of the most likely reasons for sterile control failure.

It has been discovered through a study that 11% of sterilisation attempts fail because of a malfunction in both types of sterilisers.

Leaving part of the cleaning before sterilisation will allow dirt and organisms to remain on the instruments. Due to the biofilm, microbes can survive despite very hot cleaning cycles.

The quality of wraps and containers can vary significantly. When you use materials that do not match your sterilisation process, the cycles usually do not complete, which often leads to problems in instrument sterilisation.

According to one test with VHP, approximately 76% of soil-covered surgical instruments remained contaminated unless they were first properly cleaned.

There are situations when something goes wrong simply because someone did not follow the instructions correctly, placed the clothes in the wrong location, or selected the incorrect cycle setting. Sometimes, even those with extensive experience in ethics can make mistakes that lead to sterilisation failures.

Between 2013 and 2016, 74% of “immediate threat to life” (ITL) events reported by The Joint Commission stemmed from improperly sterilised or disinfected equipment.

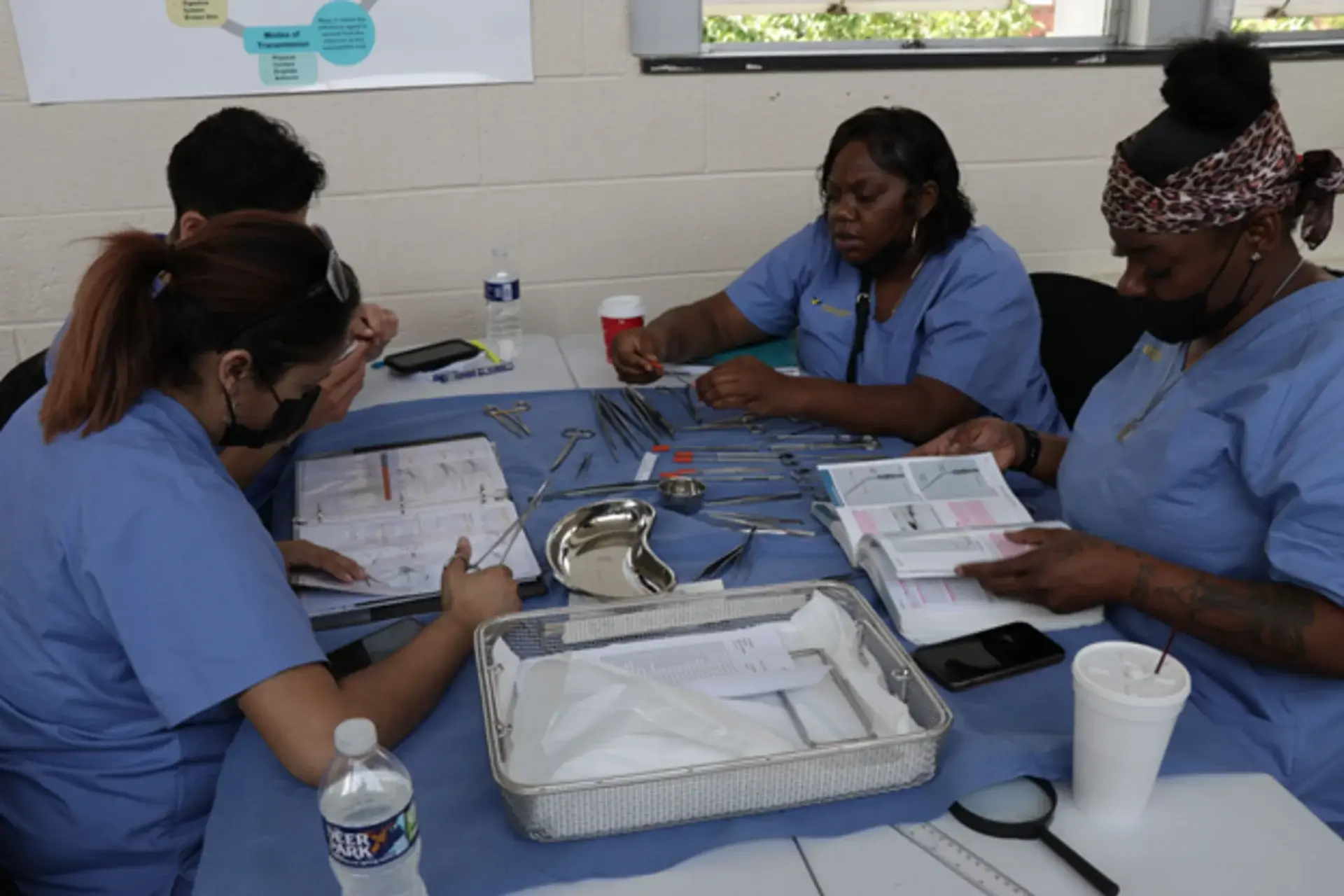

Sterile processing focuses on the importance of every detail. Even a small mistake can lead to contaminated tools, adverse patient outcomes, and regulatory infractions.

Here are three problems with SPD sterilisation that you can fix right away.

Targeted steps at a hospital reduced the number of errors in sterilising surgery instruments from 3 per 100 cases to 1.5.

They supply data to check if each step of sterilisation was carried out correctly. Not looking at them or misjudging the outcomes can be the most straightforward way for SPD errors to happen.

If documentation of the cycle logs and maintenance of equipment, along with validation logs, is ignored, both protocols and tracking of sterilisation issues are also ignored.

Running risks is what you do if your standards don’t match the current ANSI/AAMI standards. Regularly checking for errors in medical policies helps avoid essential problems that could occur with SPD sterilisation.

Although steam sterilisers are not the issue most of the time, when they are, things can get out of hand rapidly.

We’ll review the steps to take when the autoclave is not functioning and how to resolve the issue quickly.

Ensure that the temperature, pressure, and time are within the required limits. This allows you to determine whether the computer’s problem is internal or due to a user error.

Bowie-Dick and leak tests are used to spot steam leakages and air problems. Often, these tests let you find and solve the causes of failures before anything serious occurs.

Wet clothes or instruments with no new signs of bacteria are two obvious signs the autoclave is not functioning correctly due to its seals.

If sterilisation pouches are not used appropriately or trays are positioned incorrectly, it is more likely to create problems. Loading and preparing equipment properly is a good starting point for most solutions when a problem with an autoclave arises.

Suppose, while working, you notice a load that hasn’t been processed correctly. Now what? Sterilisation protocols must always be used appropriately, as failing to do so can lead to an emergency that requires an immediate and organised response.

Here’s what happens when a sterilisation protocol fails.

Separate the devices with the issues and give them suitable labels. Prevention of unintended use is crucial for reducing the risk of disease spread.

It is essential to notify the infection control department if a failed sterilisation protocol happens, and often, an incident must be recorded and the risk assessed.

Study the logs, analyse their equipment, monitor your team’s behaviour, and examine the cycle data. It is essential to identify the cause of the problem using RCA, as the issue may be due to a malfunctioning autoclave, human error, or a faulty piece of equipment.

When it turns out that the procedures were faulty, retraining becomes vital. Addressing the reasons for sterilisation failure improves the chances of avoiding further failures.

Some sterilisation failures don’t become apparent until they turn into problems in the news. However, the bright side is that most of these failures are avoidable. Minor adjustments, such as correcting mistakes during sterilisation or repairing autoclaves, can enhance safety in every procedure. Identify your weaknesses, handle problems promptly, and consistently adhere to the prescribed guidelines. Since excellence matters greatly in sterile processing, it’s a matter of preserving lives.

Read More: