A sterilisation technician is the unsung hero of the healthcare system. These technicians are crucial in ensuring patient safety. Their rigorous labor comprises cleaning, disinfecting, and sterilizing medical tools, limiting the spread of illnesses and maintaining public health. Let’s examine a normal day in the life of a technician doing a sterilisation job in the US.

Getting ready and checking the instruments, their availability, their working condition is all what a morning routine of a central service technician comprises.

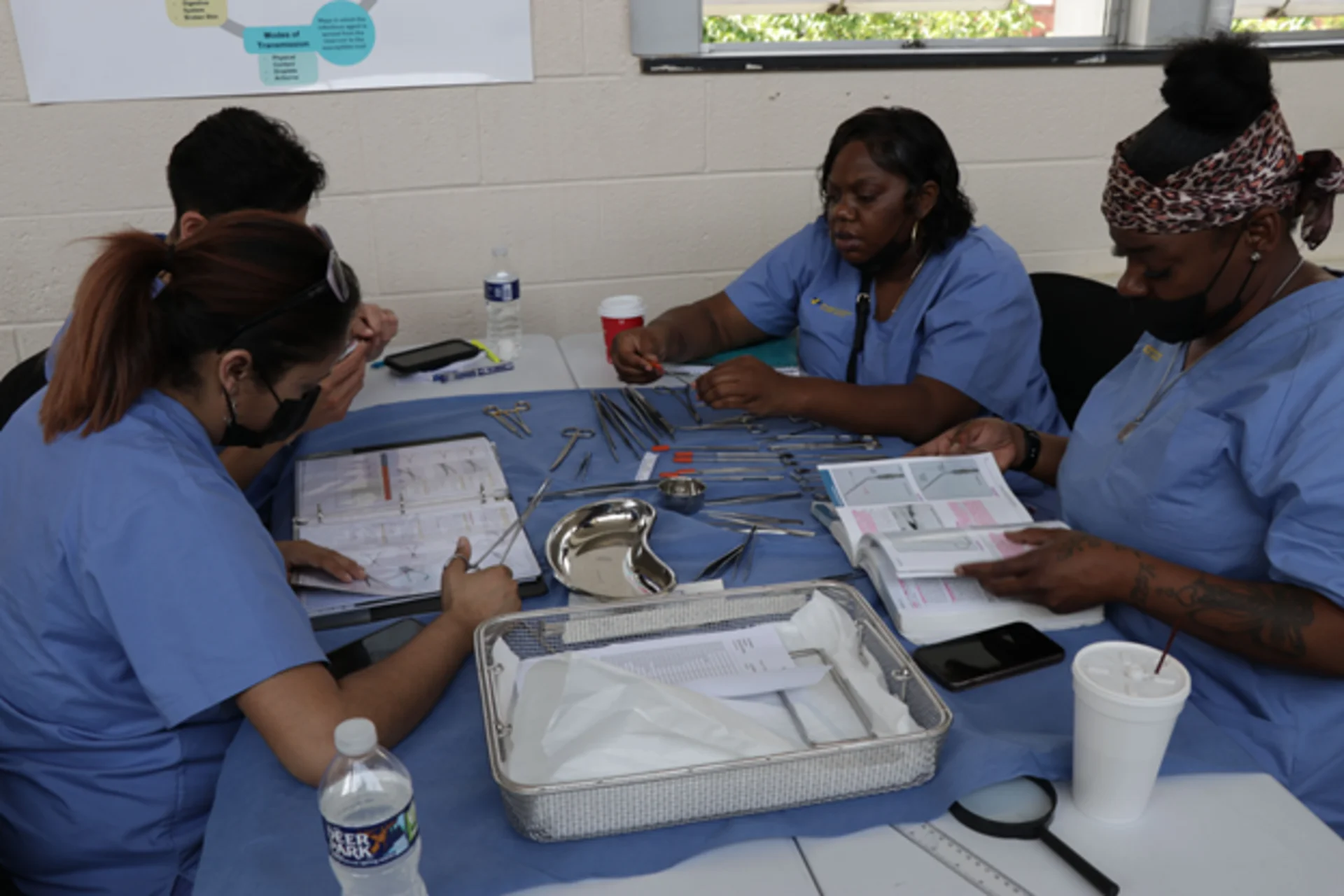

Usually, a sterilisation technician starts their day by carefully examining the sterilization apparatus to make sure it is calibrated correctly and operating as intended. They then go ahead and collect the used instruments from different operating rooms, emergency rooms, and other departments in the hospital. These tools can be as basic as surgical scissors or as sophisticated as a laparoscopic apparatus all these practical hands on training you will learn while practising sterile processing training in Philadelphia technical Institute

A central service technician thoroughly inspects each instrument to look for any obvious organic matter or trash. After that, they put the instruments in a decontamination washer, which eliminates heavy pollutants by using pressurized water at a high temperature and a detergent solution. The technician physically cleans the instruments after the washing cycle, making sure that all nooks and crannies are clear of debris. The sterile certification program in philadelphia gives a financial stability to all young adults looking for magnificent career in health care

The tools are meticulously wrapped in sterile pouches or wraps once they have been cleaned. It is essential that the tools remain sterile in this packaging until they are utilized. After that, the bundled instruments are put inside a sterilizing chamber, which may be a low-temperature gas sterilizer or a steam autoclave.

The sterile processing technician keeps a careful eye on the apparatus during the sterilisation procedure to make sure that the right pressure, temperature, and time constraints are fulfilled. All these basic information you will get to learn in an well reputed sterile processing training institute After sterilisation, biological indicators are utilised to check the efficacy of the treatment. Sterile certification training in Philadelphia equips students with the skills to clean, disinfect, and sterilize medical instruments, ensuring patient safety in healthcare setting The spores of a particular microbe present in these indicators are resistant to sterilisation. The sterilisation procedure was successful if the spores are destroyed.

After cleaning, packing and ensuring the quality, these skilled trades sterile processing technicians ensure that instruments are carefully maintained in a clean, dedicated place. When surgical operations or patient care call for the tools, the technician is in charge of keeping track of them and making sure they are available.The sterile certification training programs combine classroom learning with hands-on practice using industry-standard sterilization equipment Maintaining a record of instrument sterilization and adhering to regulatory standards both depend on accurate recordkeeping.

Sterile processing training also prepares technicians for keeping the sterilization space tidy and organized in addition to their major responsibilities of cleaning, disinfecting, and sterilizing devices. They might also help with hiring new employees, maintaining equipment, and managing inventories.

For having a successful career in trades, a sterile processing technician must pay close attention to detail and should be prepared to do some physically taxing tasks, including long night shifts. They frequently operate in a hectic setting where there is a steady stream of instruments that need to be processed. Graduates are prepared for sterile certification in philadelphia exams and entry-level roles as sterile processing or central service technicians.

There are also big perks associated with the profession. The average salary of a sterile technician in the US is $71,111. Apart from the monetary benefits, a vital part of preventing infections and guaranteeing patient safety gives a sense of satisfaction to skilled trades technicians. Their efforts have a direct impact on the general standard of care that medical facilities offer.

The equipment and techniques for sterilization will progress along with healthcare technology, leads to better sterlization technician job In the future, robotics and automated systems might be more prevalent since they simplify the sterilizing procedure and lower the possibility of human error. But to guarantee patient safety, a sterile processing technician must keep in mind the basic ideas of cleaning, disinfection, and sterilization.Certified central processing technician professionals enjoy strong job prospects and career advancement opportunities

Read More: