The impact of the COVID-19 pandemic has now developed worldwide, leaving a path of devastation in its wake. So today, the role of a sterile processing technician has become quite essential in this COVID period. Nonetheless, a sterile processing technician deals with sanitization and cleaning several medical types of equipment in the healthcare industry.

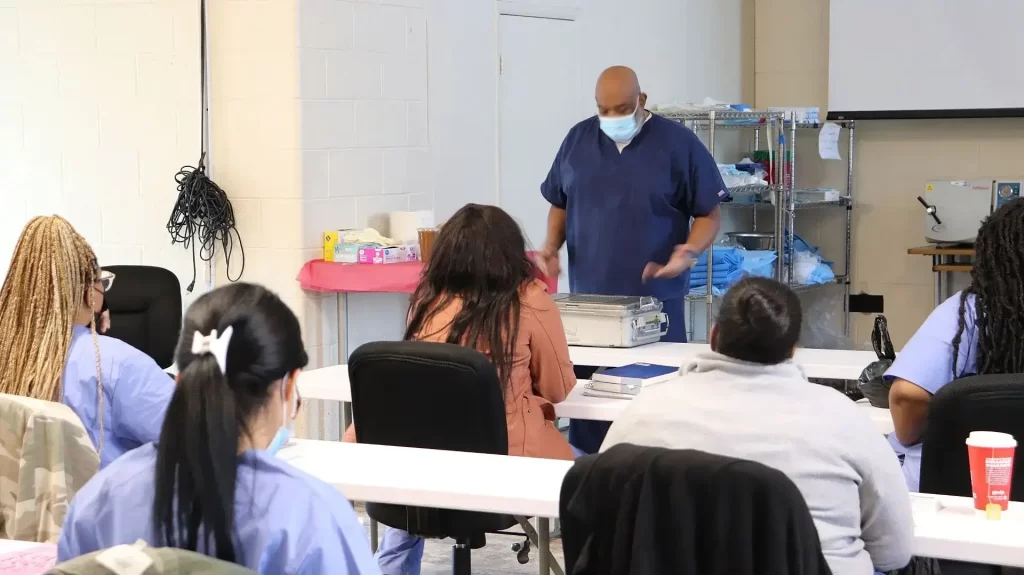

Consider seeking a professional training program if you admire becoming a registered central service technician.

Disinfection and Sterilization are vital for ensuring that medical instruments do not carry infectious diseases to patients. Indeed, the sterilization process can also be done using steam under pressure, dry heat, plasma, and liquid chemicals. In addition, wet pasteurization or liquid chemicals are also commonly used to disinfect objects in health care surroundings.

Notwithstanding, depending on what you want to disinfect, different types of Sterilization are significant. For instance, critical objects that contact infected body parts require high-level Sterilization. Apart from that noncritical ones that only affect the skin need low-level Sterilization.

As a professional sterile process tech, you will get an opportunity to master these skills in your journey.

As per the statistics and research studies, Sterilization is proper by almost 100%. The newest advancements in technology enhance the treatment of medical instruments and devices. On the contrary, much of this treatment uses different chemicals or dry heating.

It helps in assuring that procedures used in hospitals and other pharmaceutical institutions are as germ-free as possible. To ensure the protection of medical practices and reduce infection risk, the treatment of medical instruments is predominant.

Consequently, by enrolling in a reputed sterilization technician training, you can learn all the fundamental workings of Sterilization and disinfection.

There are many benefits to Sterilization, but the foremost one is killing bacteria and germs. Besides, it also gets discarded of any excess blood or other foreign particles that supplies could leave behind.

Indeed, depending on to who these unseen particulates are associated. There could be direct consequences for the neighboring patient. As a result, certified registered central service technicians normally enjoy an upper hand during the recruitment process. The current placement rate for a sterile processing technician is around 92 percent.

Indeed, sanitizing helps limit the area where these surviving germs can grow regardless of what stays behind. If you wish to work in different cities of Philadelphia, then you might have to obtain a license. Cities such as Drexel Hill, PA; Maple Shade, NJ; Haddonfield, NJ; Northeast Philadelphia and southwest Philadelphia employ those who have taken up a certification examination.

All sterilized processing technicians must follow three main steps in the sterilization process to ensure maximum patient care.

The cleaning and disinfecting stages are ample universal, but there are several different ways to sterilize. Admittedly, the job role of a sterile processing technician may seem moderately easy. Yet, this career journey is full of challenges.

Undoubtedly, the role of sterilization is critical in the healthcare industry during this COVID era. A regular working day of a central processing technician is quite challenging. Nevertheless, anyone can enroll in a sterile processing program to tackle problems while protecting themselves and their patients.

Nowadays, the rate of healthcare employment has been firmly growing at about 5 percent every year. If you desire to become such a profession, consider sterile processing technician certification programs today!

Read More: