Sterile processing has always had a significant role in the hospital. Sterile processing technician is also called the heart of hospitals. Their job roles are diverse, and they have to overlook plenty of duties. The COVID-19 pandemic has changed many things when it comes to sterile processing technician operations.

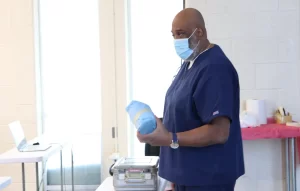

Sterile processing technicians are the hearts of the medical industry. They apply sterilization methods acquired from sterile processing schools to ensure that surgical instrument is free from contaminants.

They often investigate microbiology and infection prevention to properly retain their skills in medical tools. They may even consider contamination risks in surgical settings.

Sterile techs supervise a surgical team. They need to overcome problems and keep patients safe. These technicians are also responsible for hauling and storing sterilization and surgical supplies.

These people are helping in emergency surgery which is still occurring, but the volume is extensively less than elective surgery. Besides, the SPD technician’s role in instrument processing has increased.

Some technicians may be repositioned to other supportive roles where they are growing high. Durable medical equipment disinfection and cleaning is one such area. As the crisis ends, hospitals and medical personnel will do every possible thing to be done for patient safety and care.

Due to the deficiency of N95 masks, some larger hospitals and health systems are functioning on methods to sterilize the ones they can reuse. Hospitals are working together to manage these shortages. In fact, the sterile techs were discovering ways to disinfect the disposable masks to safeguard healthcare workers.

Sterile processing technicians are also working with researchers, engineers, and others to convey their knowledge. They used to give proper guidelines on cleaning, disinfection, and handling of these items.

sterile processing does all the cleaning and disinfection of a variety of instruments. Technicians also manage code carts and intubation equipment in much more significant demand than ever before.

One hospital that typically used or exchanged four to nine code carts a day is now using 38 to 50 due to the increased demand during the pandemic. Cleaning and restocking code carts is a high priority for sterile processing technicians.

As hospitals adjust to the COVID ups and downs, SPD techs may be discovering new techniques or having to pursue updated protocols. Sterile processing technician training ensures the quality of work and adherence to guidelines. While COVID-19 is highly virulent, they need how to properly sterile the equipment.

The sterile processing technicians are trained to treat every item as contaminated. The work of sterile technicians has always been vital, but disinfection and cleanliness are currently in the spotlight. This outbreak is supplying the world with a lesson that each SPD worker should know about personal protection, hand hygiene, and environmental awareness.

It’s impossible to understate the COVID effect on the SPD. Some SPD technicians have been diverted from cleaning their specific instrument sets to sterilizing all supplies and gear. They also need to clean a high volume of instruments as compared to pre-pandemic levels of 6-8 per day. As we are adjusting to a post-pandemic reality, today’s sterile processing continues to encounter these challenges:

Healthcare systems are hard-pressed to discover specialized central service technicians with adequate sterile skills and experience. High turnover rates can affect a hospital’s ability to meet the surgical need and prevent the cases of SSIs regularly.

Some equipment is harder to clean, and SPD technicians have to engage more than ever before. For example, an SPD tech’s visual examination for damage is more likely to fail without the proper assistance of magnification.

SPD techs may handle the burden of processing instruments faster. It further results in mistakes and potentially affects the patient.

Together, these challenges create a significant drain on hospital finances. In order to meet staffing shortages, hospitals are increasingly visiting agencies to fill vacant positions. Moreover, poor equipment management takes its toll. When tools are damaged, or inventory is not kept properly, then SPD technicians need to comprehend the basics of sterile processing. In addition, the improper sterilization of complex equipment is harder to clean, improving the chance of SSIs.

Undoubtedly, COVID-19 has massively impacted the healthcare industry. Due to this, the roles of sterile processing technicians are increased in many parts of the world. Few of the counties booming the roles of sterile technicians are north Philadelphia, South Philadelphia, Oda, Haddonfield, NJ, and Pennsauken, NJ. Thus, joining the healthcare industry is the right career choice today.

Read More: