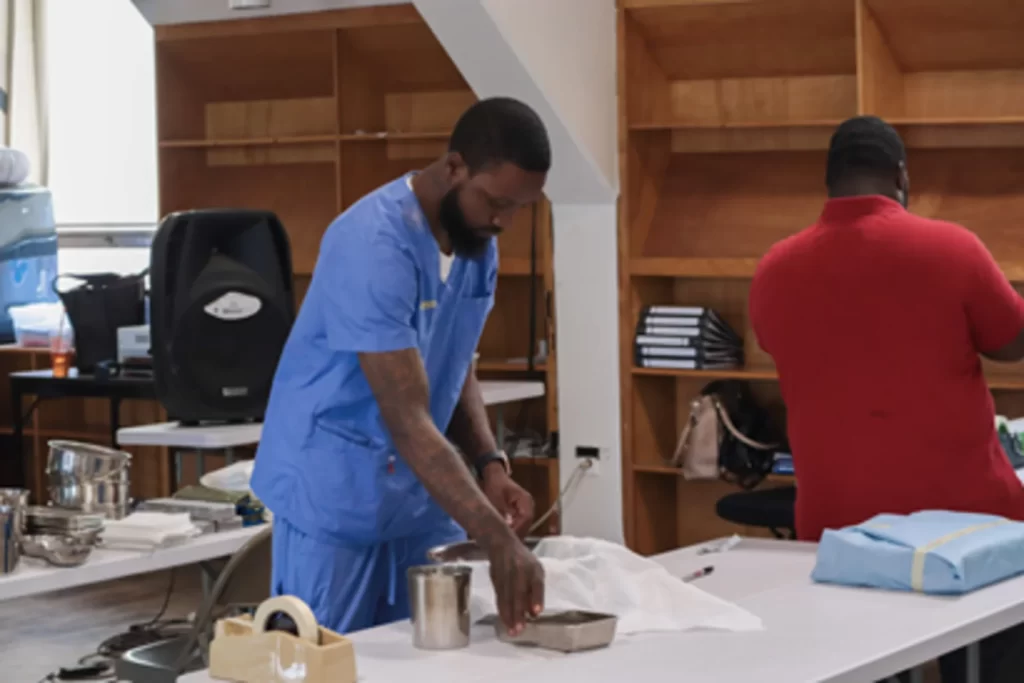

To ensure that surgical instruments are safe for patient usage, sterile processors is a crucial component of healthcare. To stop infections and make sure the equipment is functioning properly, cleaning, disinfecting, and sterilizing it is important. The medical personnel in charge of carrying out these duties are sterile processors. It is crucial for sterile processors to keep up with the latest technologies to ensure they are performing their duties properly and effectively.

Examining the advantages of technology, the risks of not keeping up with it, and the difficulties that sterile processors could have while implementing new technology are all major reasons why sterile processors should keep up with the newest developments.

Technology has completely changed the way sterile processing is done, making it quicker and more efficient. Here are some advantages that a central sterile technician may gain from keeping abreast of cutting-edge technology:

New technology streamlines the sterile processing workflow, reducing the time it takes to sterilize equipment. Automated equipment can perform many repetitive tasks previously done by hand, freeing up sterile processors to focus on more complex tasks.

The latest technology can help ensure that medical devices and instruments are properly cleaned and sterilized, reducing the risk of infection. For example, new sterilization methods, such as hydrogen peroxide gas plasma sterilization, can provide a higher level of microbial reduction than traditional methods, such as steam sterilization.

To ensure equipment is properly cleaned and sterilized before use, central sterile technicians might employ technology to monitor and track the cleaning and sterilization process. This lessens the possibility of infection and guarantees that the equipment is working properly, both of which can assist minimize equipment failure during surgery.

Sterile technicians can ultimately save money by utilizing the most recent technologies. For instance, automated equipment may save labor costs by handling monotonous jobs, and innovative sterile techs can cut down on the need for pricey tools and materials.

Here are some of the risks that central service technicians may face if they do not keep up with the latest technology:

Failure to adopt new sterilization methods or equipment in sterile processing job can increase the risk of infection for patients. Outdated equipment may not be properly cleaned or sterilized, which can lead to the transmission of infectious diseases.

Without the latest technology, sterile processing workflows may be slower and less efficient. This can lead to delays in surgeries and increased wait times for patients.

Outdated sterile equipment may be more expensive to maintain and repair, leading to higher costs for healthcare facilities.

Without the latest technology, central service technicians may have difficulty monitoring and tracking the cleaning and sterilization process, leading to lower quality control and increased risk of equipment failure.

While there are many benefits to adopting new technology in sterile processing , there are also challenges that sterile processors may face. Here are some of the challenges that they may encounter:

Adopting new technology can be expensive, especially for small healthcare facilities. New equipment and software may require significant investment, which may not be feasible for some facilities.

New sterile equipment technology may require additional training for sterile processors. This can be time-consuming especially if training needs to be done for many staff.

Some sterile processors may resist change, preferring to stick with standard methods and equipment. So are they resistant to change.

In conclusion, staying up to date with the latest technology is essential for central sterile technicians to improve the quality of their work, increase efficiency and safety, comply with regulations, and continue their education. In addition, investing in the latest technology can help ensure that sterile processing departments can provide the best possible care to patients while also improving the working conditions for sterile processors.

Read More