Have you ever wondered, when you turn the valve of your sink, what causes the water to gush out of the tap? What causes gas to leak from your gas cylinder to your stove when you need flames to satisfy a midnight hunger? Pipes, to be precise. Pipes have been around for a long time. Traveling from a faraway source to the destination of your doorstep, via the walls and directly under our feet, pipes constitute a larger supply framework of pipelines that simplifies our life multifold. Our forefathers invented this technology in 5000BC, and with it emerged pipe fitting.

What are the changes seen in pipe fitting techniques?

In the piping industry, innovations in pipe fitting have proven to be game-changing. What equipment and techniques are used in pipe fitting?

What is pipe fitting?

Pipe fitting is simply the installation and repair of pipes and tubes. But it can be tricky when you do not go for a proper plumbing certification program. We often experience situations where we must alter, break, reduce, avoid, or reverse fluid flow through pipes. As we know, pipes are used to move liquid or sometimes gas from one point to another. Pipefitters, also known as ‘fitters,’ are primarily responsible for this. It is mainly accomplished via the interface between two pipes, which links them. Depending on the desired outcome, these interfaces are carefully chosen. Plastic, copper, aluminum, carbon steel, and other materials make pipes. A pipe fitter’s role ensures that the correct pipe material is used for the proper purpose and setting.

What are pipe fitting connections like?

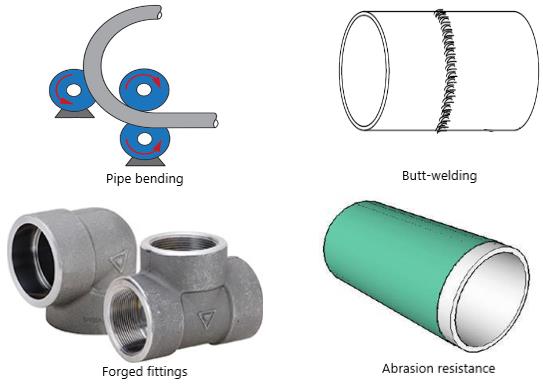

Pipe fittings usually refer to the components employed to join pipe sections and numerous fluid control products like valves, compressors, and pumps to construct the pipelines. In today’s generation, the common connotation of fittings is attributed to only metal and plastic pipes which carry fluids. However, numerous other variations of pipe fittings are prominently used to establish a network of connecting pipes for handrails and other architectural elements. These fittings usually undergo multiple processes to acclimatize to the required application: they can be welded or threaded, chemically adhered, or mechanically joined depending on various factors, including the material of the pipe. This means that pipefitters are usually trained for welding skills and other job demands.

How to choose pipe fitting materials?

Choosing the pipes depends on the environment, material properties, and working conditions. For example, metal pipes corrode quickly in acidic environments, so plastic or PVC pipes are better options. Repairing and maintaining pipes is another duty. Any pipe reaches its maximum age, beyond which it must be replaced or repaired if it develops an unforeseen fault.

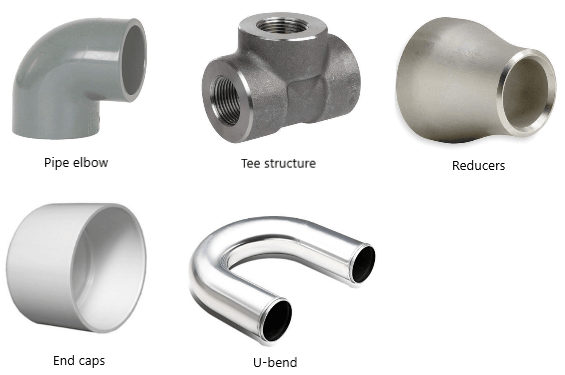

Interfaces are also known as pipe fittings. Pipe fittings are used to regulate the flow of material inside the pipe. Depending upon the material flow, appropriate pipe fitting is selected. There are many different categories in pipe fittings. Some are given below.

Because ancient pipe fitting techniques are still used today and age, much labor and time are lost. The companies in the piping industry have spent a lot of money on these old methods. What can change this? What new approaches and resources are available to help with this problem? Let’s see what happens.

High-Pressure Elbow- Connections and Application

One of the most crucial components in the pipe fittings includes a high-pressure elbow comprising a curved pipe bending- with a unique characteristic of having a connected shunt straight channel. These are reasonable structures that aim at evenly distributing the piping stress, facilitating convenient operation, reducing the pipeline resistance, and eventually optimizing the pipeline arrangement that is highly economically viable due to cheap investments, reduced operational costs, reduced piping vibrations, ensuring long life and safe operation of the equipment and pipeline. This part of the pipe is usually constructed with cast iron, stainless steel, alloy steel, nonferrous metals, etc. The connection thus established can be a flange, thread, socket, or spigot joint.

Pipe fitting conjunction – Stainless Steel

Stainless steel is one of the most preferred materials in the manufacturing of components of pipe fitting. The main advantages of stainless steel are; Simplified operation: The conjunction of stainless steel is easy to manufacture and can be operated professionally through simple training. The prominent attribution is that stainless steel exhibits stabilized engineering quality, raises working efficiency, and overcomes the complexities involved in the installation technology. In addition, ease in maintenance: The unique flexibility, characteristics like anti-shock, anti-shrinkage, welding, and expansion exhibited by stainless grooves tend to be more adaptable to temperature changes and reduce the damage to major structural components.

Main attributes in pipe fitting

Usually, through various components like bends and fittings, pressure drops can be significant depending on the length of the system. These losses play a massive role in multiple such constrictions in the construction and minimal inclusion of straight pipes. They are thus engineered carefully by computing the equivalent length of such pipes for each component. Therefore pipeline engineers play a crucial role in maintaining efficiency in the long run by verifying the minor losses in the construction.

As we can see, the job of a pipefitter is manifold, so we need a pipefitter school for better training. They are responsible for holding constructions together. A career as a pipefitter is definitely in high demand with such a demanding and fulfilling nature of work. Many industries find the use of trained and certified pipefitters in the job from plumbing programs. With training in different skills such as welding, pipefitters are a valued asset in the industry and have various job opportunities all over the globe. You can become a certified pipefitter with training in as little as six months. With one of the best plumbing trade schools in Philadelphia, you can give your career the boost it needs. With construction on the rise and economies getting back stability, pipefitter training will pay off with an excellent career for future success.

As we can see, the job of a pipefitter is manifold, so we need a pipefitter school for better training. They are responsible for holding constructions together. A career as a pipefitter is definitely in high demand with such a demanding and fulfilling nature of work. Many industries find the use of trained and certified pipefitters in the job from plumbing programs. With training in different skills such as welding, pipefitters are a valued asset in the industry and have various job opportunities all over the globe. You can become a certified pipefitter with training in as little as six months. With one of the best plumbing trade schools in Philadelphia, you can give your career the boost it needs. With construction on the rise and economies getting back stability, pipefitter training will pay off with an excellent career for future success.

Discover pipefitting possibilities at PTTI.Discover Program

Discover Endless Possibilities with pipefitting program at PTTI.