Friction, Inertia, and Laser are no longer just terms one learns and forgets as part of middle school or high school physics. But they have begun to impact the technological enhancements in various fields, chief among them being under the microscope for this article – the art of welding technology.

The world has come a long way since spot welding and inert gas arc weldings techniques like MIG or TIG. In the 21st century, technology has surpassed all reasonable expectations. Bond villains use lasers to control the world. Porsche, yes, uses micro laser welding to machine its parts to make them lighter, stronger, and faster.

Elihu Thomson, the man who invented resistance welding and snowballed modern welding technology, would be spiffed to see such fantastic tech.

Porsche uses a proprietary Aluminum alloy called M174+ and uses metal dust in a Laser Metal Fusion process to make their pistons in what can only be comprehended by the untrained eye as 3D printing metal parts!

In a process that takes over 12 hours and 1200 layers of micro-welding, each layer is less than 1/10th millimeter thick; here’s where they’re using another cutting-edge tech – robotic welding.

Topping the list of buzzwords today are terms like Artificial Intelligence, Machine Learning, and Deep Learning. Well, this process uses Machine Learning to finalize the schematic design. The engineers’ team uploads a topological schematic to the system, simulating the load and the possible pressure points. Then it eliminates unnecessary materials for the micro-welding, resulting in unique architecture and design. This AI-based design has also generated strategies for pistons with incredibly advanced cooling galleries where oil circulates to maintain safe operating temperatures. AI for welding produces a highly intricate design that results in robots creating previously impossible* metalwork like honeycomb structures within a piston combined with laser welding’s technological advancement. (*: By using traditional methods like casting or forging)

The types of welding are categorized based on how two or more workpieces are joined.

With the advent of newer technologies, we will quite possibly need to add more types!

Although we have not used trains much in the last year, scientists and engineers have continued to use their brains, and they have made some brilliant strides in the development of rail welding technologies. As long as one does not slight towards hedonistic tendencies, they should comprehend the Flash-Butt welding machines that have replaced the usual devices used for rail welding. These old devices employed high voltages of electricity to create high temperatures that fused the rails’ two ends. These improvements are crucial to the whole country as most people use trains for long-distance travel and each improvement here impacts the people directly. Furthermore, these are entirely automated machines that make flawless, accurate, and regulated results while also performing actions in extreme temperatures and conditions, showing that they can be helpful in any country and any state!

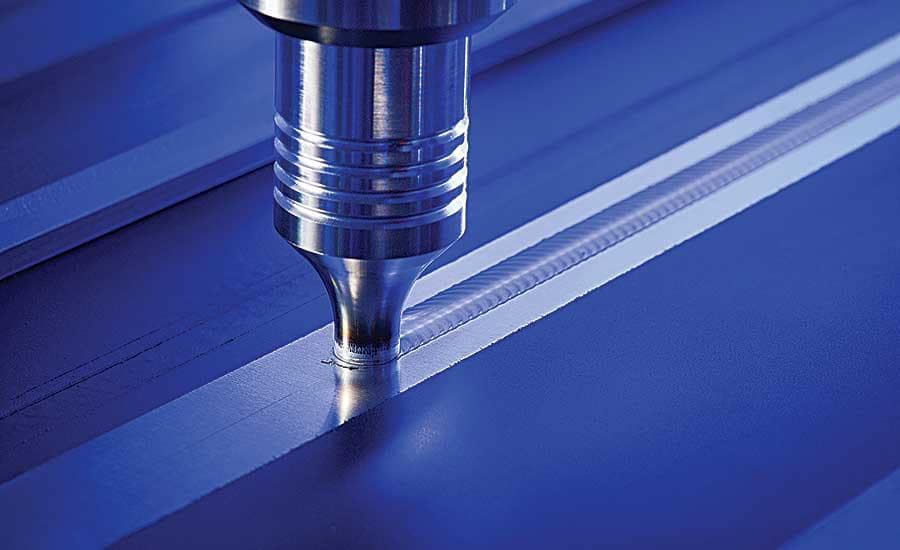

Friction Stir Welding is a relatively recent technique of welding that is now in use. This method works by using a quickly rotating tool that holds a softened version of the material and is in continual touch with the two sides of the metal that have been welded together. The heat generated turns the tool’s softened material into a solid phase weld and joins the metal’s two sides. It is like Laser Welding because both of these methods do not need any filler materials, and they are both used to weld aluminum and other alloys. Further, when the required parameters meet through adequately restrained components, these technological advancements in welding result in a high-quality strong weld while producing negligible distortion levels without having fumes or radiation and is also energy efficient!

The virtual reality world has also made giant strides and contributed to advancements in welding technology. It has served as a tool, making a significant impact on welding training. VR can command a virtual environment with a potentially exhaustive list of possible welding techniques. A basic virtual reality headset with a suitable controller to detect tiny movements will set you back a few hundred dollars. But the gains of never having to invest in training material, metals, training equipment, or allocation of working equipment for training purposes will sway the argument in favor of Virtual Reality headsets. You have the freedom to practice your welding skills using VR without exhausting actual materials and resources, and neither do you cause any wastage. The welding technology program from one of the top welding schools in Philadelphia offers you this Welding training using VR as part of the course.

The world has advanced with excellent work in progress in welding technology, and these skills are ever in demand. The advancements play a huge role in keeping these techniques and skills relevant and welding in demand, and the current trend proves that this is indispensable. Therefore, joining a welding technology school to get certified welding training can significantly boost your career!

Read More:

Don't miss PTTI's welding training!Discover Program

Don't miss out on the training at PTTI's welding program.