The micro-welding program involves performing metal fusion at a microscopic scale. The welder has to use a microscope to see the process of the micro-welding program. Also known as precision welding, this specialized micro-operation requires accuracy and expertise. In micro-welding, a typical bead size can be as large as .065 and, depending on the scenario, be as small as .005.

The history of micro-welding goes back more than one hundred years people learn a little about it in welding school. Ford company first tried the micro-welding technique. They used it to weld the metals within the vacuum tube with a high melting point. They had to resort to this technique, as standard soldering would not have survived high melt points.

On the other hand, micro resistance welding was also used in orthodontic instruments. However, orthodontic appliances could not use all metals because of the human body’s internal use. Therefore, the micro resistance welding technique was used to join nonferrous metals.

Micro welding innovation became inevitable because of the welding needs of nonferrous metals like nickel, tungsten, and molybdenum. Hence modernization came through, and emission-type welding replaced old resistance welding.

The initial days’ story is interesting for tools and dies welding, as hydrogen gas and two tungsten electrodes were used in the process. After that, it was merely a process of creating excess temperature on the steel to burn it for welding.

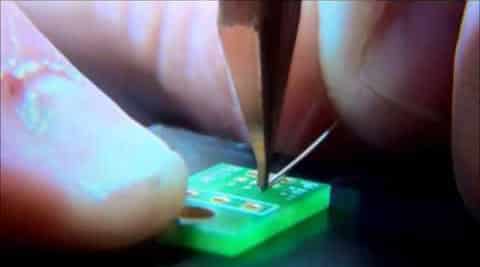

Later on, the electronic sector understood the full potential of micro-welding. This high-quality, sophisticated micro-welding procedure, on the other hand, aids in the precise joining of small electronics components.

Micro Welding equipment is also evolving with time. Machines used for micro welding were giant but small and easy to carry. Torches used in welding have also seen innovation to create ease for the welder. These torches are smaller and easier to handle. In addition, the lenses available are welder friendly and help the handler to focus on defined weld areas.

Micro welding uses mini TIG apparatus, which is like the size of a pen, and it demands focus and precision from the worker. Since the reference here is to weld minimal components, little heat is required to safeguard surrounding areas. Therefore, as per the defined process, a first product evaluation is done to determine temperature levels. And, one needs to use these products wisely, so getting proper training from welding school is mandatory. Evaluation is to ensure that welding performance is not damaging the product’s surface. Modern-day micro-welding equipment is competent in examining weld parameters, mechanical or electrical, and internal resistance. This makes the equipment capable of adjusting factors to deliver consistent welds.

Micro welding requires special equipment and machines due to the nature of its operation. The process has even reached a stage of automation in different industrial setups.

Many different types of welding are in use on a large scale in the industry. Below are some other micro-welding techniques that are currently in use:

A high-temperature plasma creates an arc between a tungsten electrode and a workpiece. In simple terms, heat generation through the formation of an arc performs the welding. This causes similar or different materials to melt and fuse. The material used for micro TIG welding includes pure tungsten, and other materials contain tungsten like thorium, cerium, lanthanum, and yttrium.

As shared above, resistance micro welding is the method that initiated the micro-welding process. In the procedure of resistance micro-welding, the current is received from electrodes, and the welder maintains the pressure. As a result, resistance welding can perform spot welds with high precision and quality.

Micro laser welding, as the name suggests, is laser-driven. Laser welding is very common with automated welding units. Laser welding is known for precise processes and quality joints. Lasers help in piercing deep and provide quality fusion. The laser process does not produce any gas and hence avoids surrounding contamination.

Laser micro-welding joins high-value miniature components in industries like medical, electronics, automotive, telecom, etc. It can join both ferrous and nonferrous parts of the metal piece.

Flash welding is known for producing clean joints using high pressure. It does not use any filler metals. Flash micro welding is a type of resistance welding. In the welding process, the ends of the product involve pressing together so that current and preheat generate a specific temperature. When the heating is appropriate, the parts are pressed against each other firmly and slowly, causing the melt and fusion. This can get difficult if an individual doesn’t take proper training from a welding trade school.

Micro-welding has evolved from the micro resistance process stage to a stage where laser technology is in use. Micro welding has opened a new path for engineers and welding technicians to weld all the immature materials required for any purpose they need and is evolving continuously with proper micro-welding training programs. However, innovation so far is not enough and needs to go a long way from here. Becoming a qualified welder is now more exciting than ever with the advent and advancement of technology. New opportunities, micro-welding training programs, and immense scope for the growth of a career as a welder are present today. The earnings for a certified welding technician are excellent and higher than the average salary of other skilled trades in the industry. Getting a certification from the top welding trade school in the USA can open up various career opportunities in the industry and worldwide. Welders are in high demand due to their work, and getting a welding education is inevitably highly lucrative.

Read more:

Don't miss PTTI's welding training!Discover Program

Don't miss out on the training at PTTI's welding program.