One of the essential fabrication processes in the industry is welding technology. In this process, two or more parts are fused using heat, pressure, or cooling to form a joint. Welding can be done on various metals and non-metals, which are essential in metallurgy and manufacturing. Learning about welding technology from one of the top welding tech schools can give you an edge in your career. Different types of welding take place using various techniques depending on the kind of materials to be fused. Here is a brief overview of the common types of welding, from which you can get welding certifications from the best welding trade schools in the U.S.

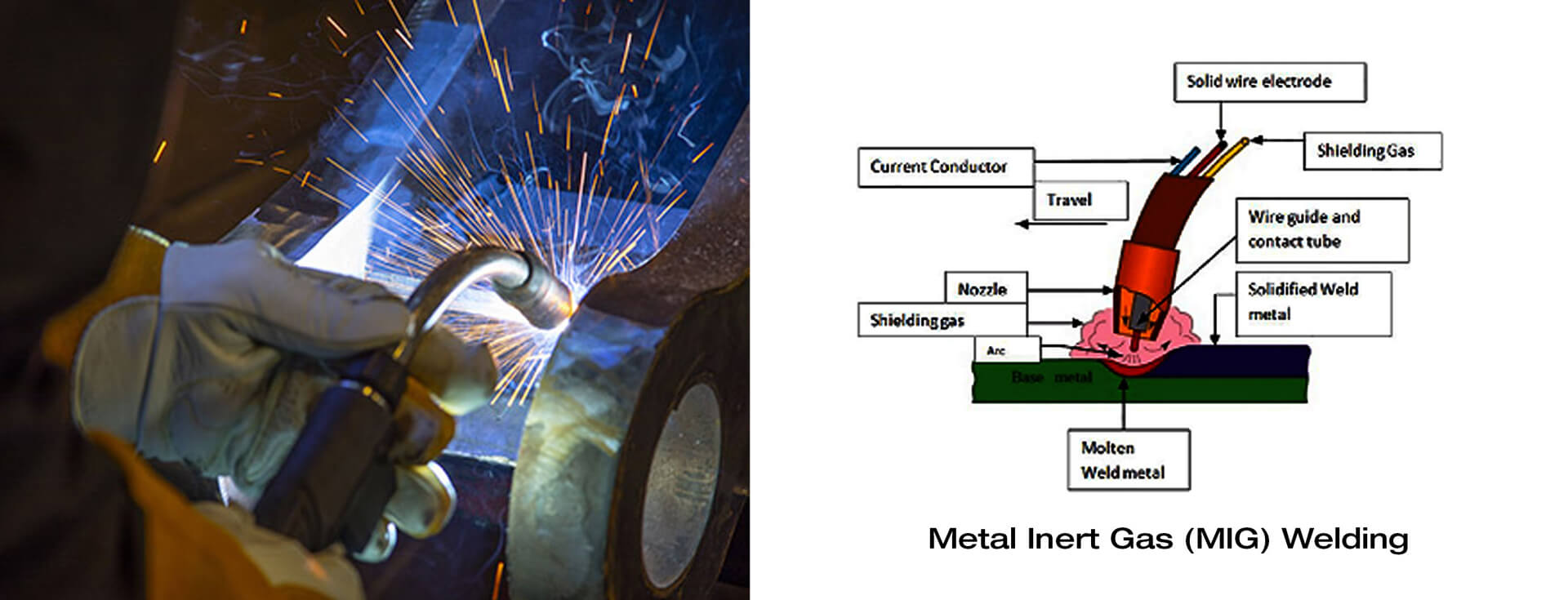

This process requires proper training from a welding certification program. In this welding process, they heat the workpiece metal(s) by an electric arc that forms between a consumable wire electrode and the workpiece metal(s), which melts and eventually cools, causing these to fuse. Inert shielding gas is supplied through the welding gun along the consumable wire electrode to shield the electric arc and prevent contamination from the surrounding air, ensuring that no surrounding gas can contaminate the process.

Metal Inert Gas (MIG) Welding accounts for more than 50% of all deposited metal welds in the industry, and it is widely used. It is a modern, improved arc welding process that is flexible and suitable for mechanisation. It is a highly lucrative and sought-after skill in welding, fabrication, and metal joining companies in the Tri-state area. Welding Certification in this technology will give you an edge as a skilled welder. A high degree of manipulative skill is expected of a qualified Metal Inert Gas (MIG) Welder in the industry.

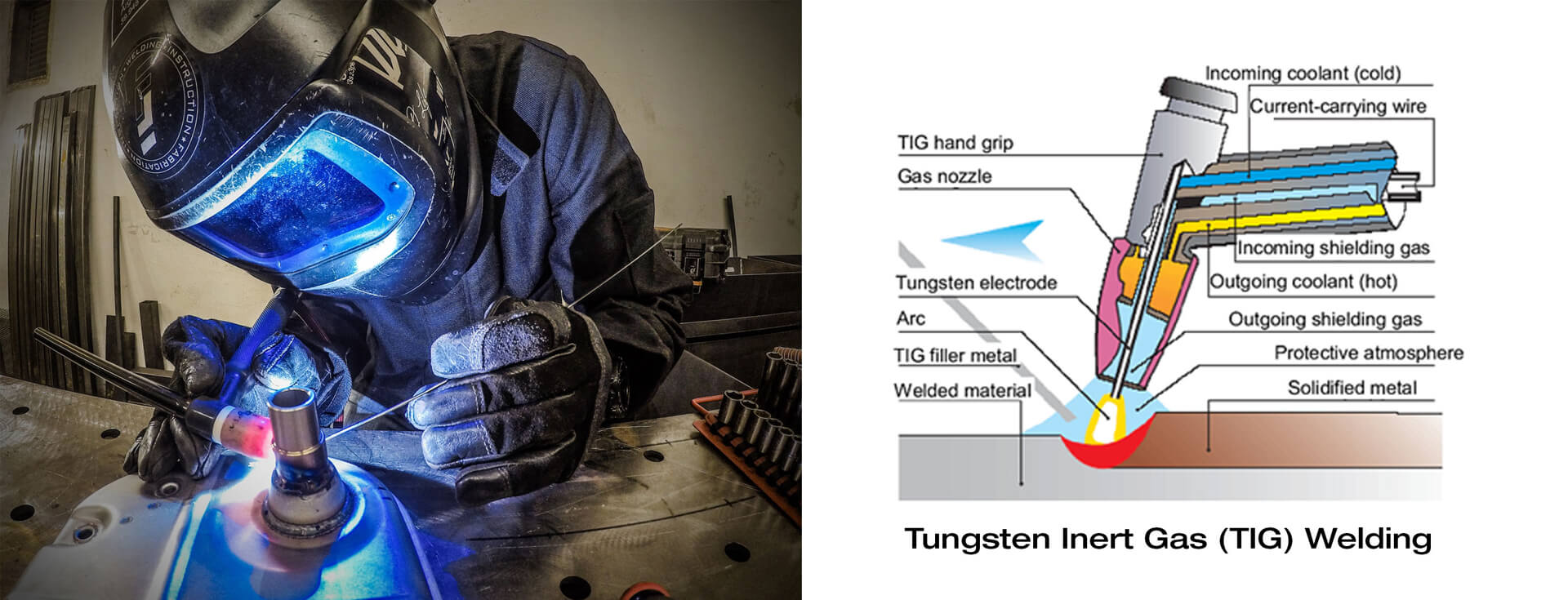

The only difference between Tungsten Inert Gas (TIG) Welding and Metal Inert Gas (MIG) Welding is the addition of filler metal in the welding process. In Tungsten Inert Gas (TIG) Welding, the heating of workpiece metal by an electric arc formed between the workpiece metal and a non-consumable Tungsten wire electrode, where the use of filler metal is to add to the weld pool (where the workpiece metal and filler metal melt and eventually cool). Surrounding this area is an inert gas, usually Helium or Argon, similar to metal inert gas (MIG) welding, which shields it from oxidation and other contamination by the surrounding atmosphere.

The advantage of Tungsten Inert Gas (TIG) Welding over Metal Inert Gas (MIG) Welding is that it is suitable for all industries, but requires high-quality welding and is widely used in mechanised modes. The welding operator must be trained to examine the joints and parameters precisely. The employment opportunities that open up by learning Welding Technology from the best welding schools in the U.S can provide skilled welders the sustainability and stability in their career and scope for attaining better opportunities in the industry.

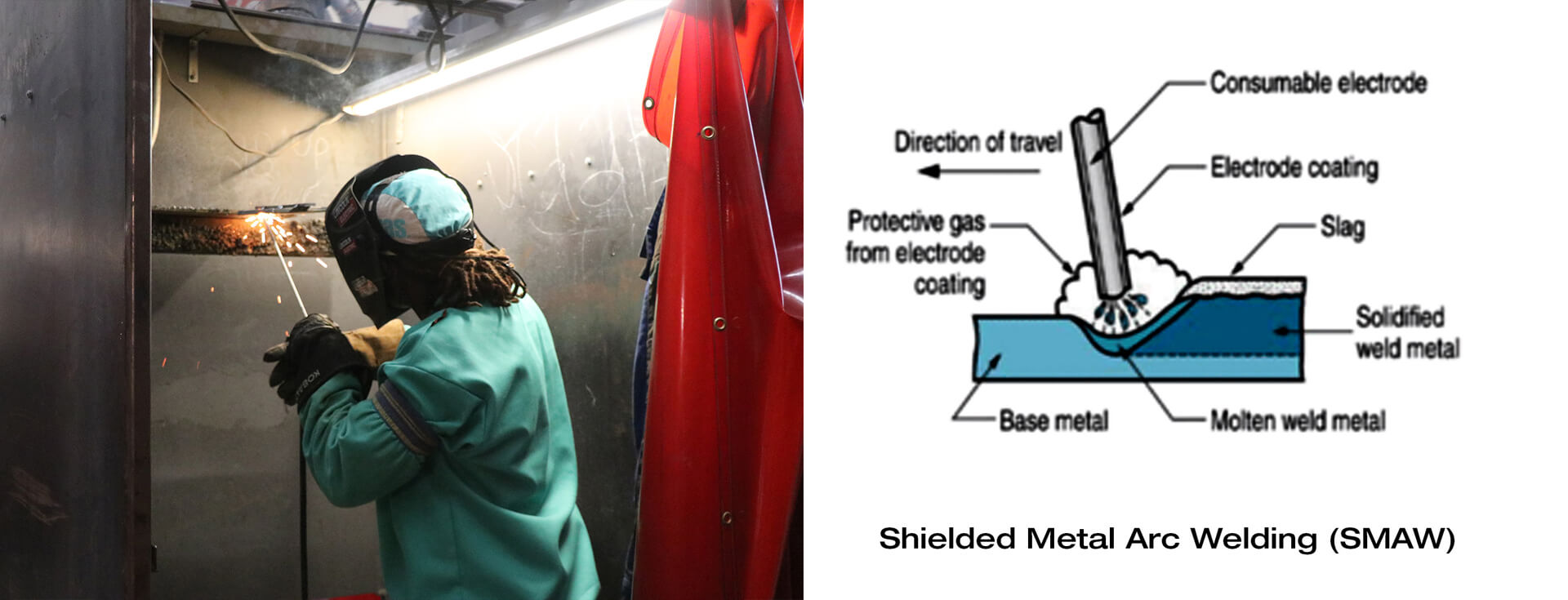

One of the typical welding techniques is Shielded Metal Arc Welding. It is a manual arc welding process that requires a flux-coated consumable electrode and the surface of the workpiece metal to melt and fuse to create the weld. In this process, gas and slag are formed during the heating, preventing contamination from the surrounding atmosphere and protecting the weld area. The slag cools off and solidifies, and must be chipped off before the metal workpiece becomes usable for the following process. The welding classes from a recognised training school, provides greater opportunities for career growth and financial stability

The welder’s skills determine the quality of the weld. So, a qualified welding technician is particularly valuable to the industry, as this versatile and straightforward welding technique is ruling the repair and maintenance sector of the metal fabrication industries.

Flux Cored Arc Welding (FCAW) is a semi-automatic or automatic welding process where the consumable electrode has a flux core and continuously gets fed. The necessary process to eliminate atmospheric contamination depends on the material in the flux core. For example, in one type of Flux Cored Arc Welding (FCAW), the core contains flux and other materials that produce a shielding gas during welding, preventing contamination by protecting the welding arc. And in the different Flux Cored Arc Welding types, an external shielding gas source is supplied to protect the weld pool from oxidation.

Flux Cored Arc Welding (FCAW) is portable, highly productive, and produces high-quality welds. Therefore, the employment opportunities for a certified welding technician in Flux Cored Arc Welding (FCAW) from a welding trade school are high due to the requirements of this technology in the construction industry, due to the portability, ease, and flexibility of operations.

There are plenty of exciting and lucrative job prospects for a fresher or industry professional with a Welding Certification from the best welding trade school in the U.S., which will help establish them in the industry and provide sustainable employment. According to Syndicate PayScale Data, a professional welder’s average annual starting salary ranges from $54,000 to $71,000. It exponentially increases with years of experience, whereas an experienced, qualified welding technician can earn $100,000 annually.

There are plenty of exciting and lucrative job prospects for a fresher or industry professional with a Welding Certification from the best welding trade school in the U.S., which will help establish them in the industry and provide sustainable employment. According to Syndicate PayScale Data, a professional welder’s average annual starting salary ranges from $54,000 to $71,000. It exponentially increases with years of experience, whereas an experienced, qualified welding technician can earn $100,000 annually.

Many industries, including manufacturing, construction, transport, and energy sectors, employ skilled, certified technicians and provide growth and mobility in their careers. Furthermore, as technological innovations and developments increase, the demand and preference for expert welders are always present to meet the industry’s needs and requirements by employing the technical and creative skills of trained and experienced workers in producing high-quality outcomes. Therefore, you must enrol in welding classes to get exposure to all these techniques.

Read more: