Cross-connection control is an essential aspect of plumbing system design and maintenance. Plumbing professionals play a vital role in ensuring that cross-connections are adequately controlled and prevented to protect public health and safety. In this article, let’s explore the role of plumbing professionals in cross-connection control in plumbing systems, including what cross-connections are, how they can occur, and what measures can be taken to prevent them.

A cross-connection is a physical link between a potable water supply and a non-potable source, such as a waste disposal system, irrigation system, or chemical supply line. These connections can occur through various means, including direct links, backflow, or siphonage.

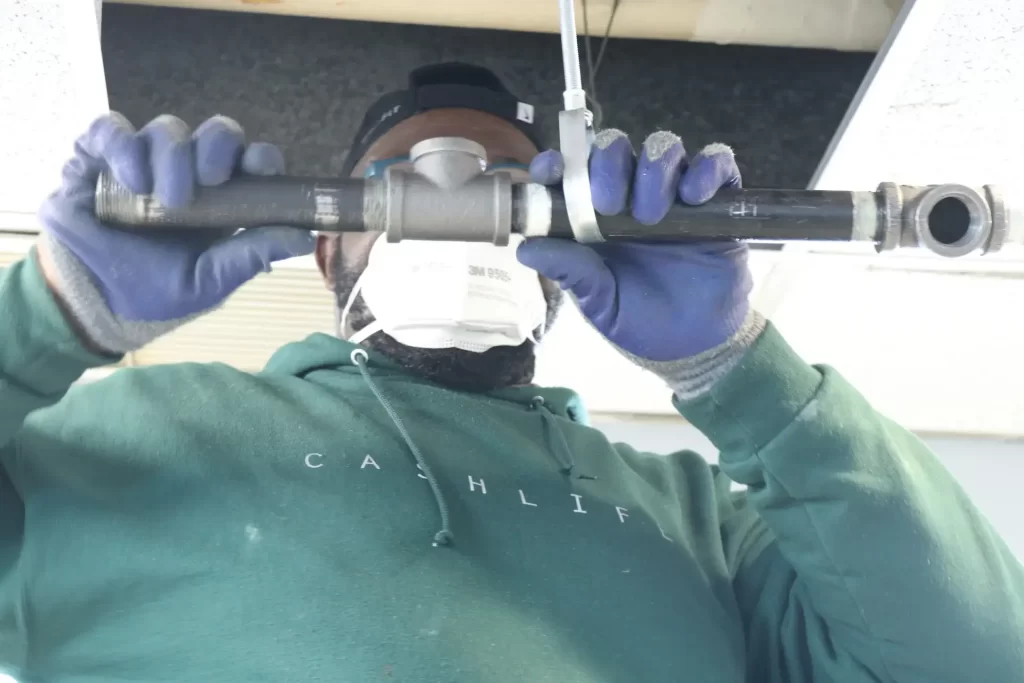

Plumbing professionals play a critical role in cross-connection control by designing, installing, and maintaining plumbing systems that prevent cross-connections from occurring. In addition, they are responsible for identifying potential cross-connections and developing strategies to eliminate or control them. Plumbing professionals in the plumbing training program are also responsible for ensuring that the plumbing system complies with local and national regulations for cross-connection control.

One of the primary responsibilities of plumbing professionals is to design plumbing systems that prevent cross-connections from occurring. This includes selecting the appropriate materials and fittings, designing piping layouts that minimize the risk of cross-connections, and  as necessary.

as necessary.

The design of a plumbing system must consider the potential sources of contamination and the risk factors associated with each source. For example, a plumbing system that supplies water must be designed to prevent cross-connections with the hospital’s wastewater or medical gas systems, which can contain harmful pathogens or chemicals.

Plumbing professionals must also consider the potential of cross-connections when designing irrigation systems, fire sprinkler systems, and other non-potable water systems. In addition, they must ensure that these systems are installed with appropriate backflow prevention devices and are isolated from the potable water supply.

Backflow prevention devices are an essential tool in preventing cross-connections in plumbing systems. These devices are designed to avoid the backflow of non-potable water into potable water by creating a physical barrier or air gap between the two sources.

Plumbing professionals in plumber education and training must ensure that the appropriate type and size of backflow prevention device are installed in the plumbing system to prevent backflow from occurring. This includes selecting the proper device based on the cross-connection type and the risk level associated with the potential contaminants.

Backflow prevention devices must be installed according to the manufacturer’s instructions and local and national regulations. Plumbing professionals must also ensure that these devices are properly maintained and tested to ensure that they are functioning correctly.

Backflow prevention devices must be tested and maintained regularly to ensure they function correctly. Plumbing professionals in training for plumbing are responsible for developing and implementing a testing and maintenance program that complies with local and national regulations.

Testing of backflow prevention devices typically involves a series of tests to determine whether the device is working correctly. These tests may include a visual inspection and functional and pressure tests. The device must be repaired or replaced if it fails these tests.

Maintenance of backflow prevention devices may involve cleaning or replacing filters, replacing worn or damaged parts, or adjusting the device’s settings to ensure it is working correctly.

Plumbing professionals must be trained and educated in cross-connection control to ensure they can design, install, and maintain plumbing systems that comply with local and national regulations. This includes understanding the types of cross-connection control in the plumbing program.

Here are some guidelines for designing plumbing systems with cross-connection control in mind:

Identify areas where cross-connections could occur, such as irrigation systems, cooling towers, and fire suppression systems.

Install backflow prevention devices, such as air gaps, double-check valves, or reduced pressure zone (RPZ) valves, to prevent backflow into the potable water supply. The type of plumbing tools used will depend on the hazard level and local code requirements.

Follow local codes and regulations related to cross-connection control. These codes will provide specific requirements for installing, operating, and maintaining backflow prevention devices.

Educate building occupants on the importance of cross-connection control and the risks associated with cross-connections. Encourage them to report any potential cross-connections they observe to building management.

Regular inspections and maintenance of backflow prevention devices are critical to ensure they function correctly in plumbing jobs. In addition, machines can fail over time, so it is essential to have a schedule for testing and maintenance.

Document the plumbing system, including the location of backflow prevention devices, inspection and maintenance schedules, and any repairs made. This documentation will help ensure the plumbing system remains compliant with local codes and regulations and can be used as a reference for future maintenance and repairs.

Overall, plumbing professionals play a critical role in ensuring the safety and purity of the public water supply by preventing cross-connections in plumbing systems.

Read More: