Welding is a process of joining together two or more pieces of material. Usually, metal or thermoplastic uses high heat to join the pieces and allows them to cool, causing fusion. Welding Fabrication is a process where structures of metal are made by cutting, bending, and assembling processes. The welding process is part of the fabrication process, where welding may be just a specialized operation in creating the entire structure.

Welding process and fabrication processes deal with joining, managing, and scraping the metal, but welding remains a more fundamental activity that requires only a single task. In comparison, metal fabrication revolves around several tasks, i.e., welding, scraping, and joining metal parts.

At manufacturing and construction sites, a couple of functions that are concerned with fabrication are often done by welders. While some fabricators also do welding occasionally. Thus, welding fabrication may include welding, but welding is always part of fabrication.

Fabrication and welding may sound a bit similar, but these terms are not interchangeable as they are very different from each other. They both involve different methods and strategies. Following are the fundamental differences between both the two processes:

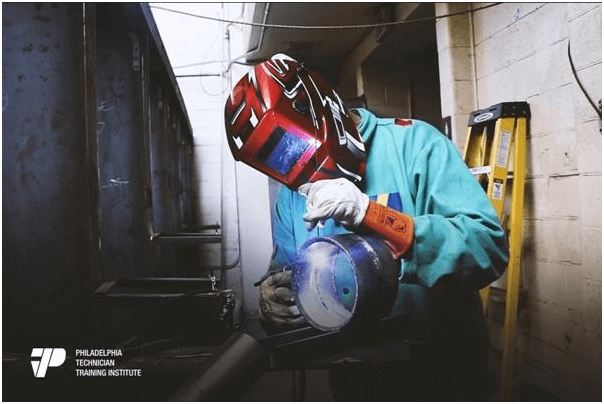

As fabrication involves several tasks, fabricators use different cutting machines, including mechanical saws, laser cutters, and plasma torches. Also, heavy machinery is used to perform some tasks. On the other hand, welding uses a dedicated welding machine, welding uses specific welding clamps, torches, power sources, and consumable electrodes. Also, welding requires safety equipment to protect the welders from harmful fumes and gases.

Fabrication is a holistic process, and fabricators often work with different machines that mold and shape the metal, whereas welders must work with hands. Welding is a work of precision and requires intense practice to join the parts neatly. With intense training and experience, only welders can join the metals ideally.Welding fabrication goes beyond welding alone, as it involves cutting, bending, and assembling metal structures.

Fabrication is a complex process involving numerous tasks, such as cutting, bending, scraping, and joining metal parts, utilizing various strategies. On the other hand, as we know, welding involves a single task, and it uses some standard Welding techniques. Such as gas metal arc welding, shielded metal arc welding, gas tungsten arc welding, and flux core arc welding.At manufacturing and construction sites, many tasks within welding fabrication are handled by welders,

The global welding market was USD 19.5 billion and is projected to reach USD 27.22 billion in 2027. Exhibiting a CAGR of 4.3 percent during this forecast period. Welding as a career option offers a lot of opportunities to people and is a good job prospect.

Many welding trade schools and colleges offer welding courses. Welder training programs or welding courses help students perform the tasks properly and enable them with all skills and expertise.

Welders are in high demand due to new projects, manufacturing plants, and new construction sites such as automotive, aerospace, natural gas pipelines, etc. The Bureau of Labor Statistics estimates a three-percent rise in Welding jobs in the next ten years.

The BLS also reports that welders can shift from one industry to another quickly because of basic welding knowledge. The American Welding Society has estimated a shortage of 400,000 welders by 2024. Shows a decreasing number of welders in the U.S due to the graying welder population. This provides a chance for the new welders to fill up their people.

Welding has become one of the highest-paid trades in recent years in the United States. With an average starting salary of over $40,000 per annum or about $20 per hour, it is one of the highest-paid skilled trade jobs. For example, the average salary for a welder is $24.49 per hour in Philadelphia. Also, with the construction industry having a solid rise, demand for welders is increasing.

To build a successful welding career, individuals can pursue a welding training program or welding course through trade schools and technical colleges. While on-the-job training is possible, formal educationIt generally takes up to a few months to a few years, depending on the course one takes. A high school degree or an equivalent. Such as GED is the minimum qualification required to become an on-the-job training worker or enroll in a welding course. Additionally, individuals who undergo on-the-job training take years to become efficient, certified welders, compared to those who take welding courses.

The Welding Industry is showing a significant boost with one of the highest paying skilled trades. It offers excellent opportunities for jobs and careers with job security as welders are in high demand.welding one of the top-paying skilled trade jobs with excellent career prospects. With the right welding training program and welding course, students can gain the expertise required to become certified welders and secure long-term success in the welding industry.

The welding training program is an investment for students who aspire to be welders. With proper hands-on training in the welding process and guidance in welding courses, students can learn many skills and experience to become certified welders..

Read More:

Don't miss PTTI's welding training!Discover Program

Don't miss out on the training at PTTI's welding program.